1-888-919-CVSS (2877) info@cvssmodules.com

Pharma

Optimize and ensure compliance with every step.

Program compliance & standards into your work flow.

The manufacturing of pharmaceuticals and cosmetics is governed by strict regulations to ensure safety, efficacy, and quality. Compliance with pharmacological and cosmetic regulations in Canada is essential for manufacturers to ensure the safety, efficacy, and quality of their products. Health Canada’s regulations are designed to protect consumers and maintain high standards within the industry.

CVSS Modules can automate…

- Raw Material Verification

- Batch Records

- Management

- Standard Operating

- Procedures (SOPs)

- Quality Control (QC)

- Environmental Monitoring

- Equipment Calibration and Maintenance

- Traceability and Serialization

- Change Control Management

- Deviation and CAPA (Corrective and Preventive Action) Management

- Regulatory Reporting and Compliance

- Training and Competency Tracking

- Document Control

- Supply Chain Management

- Audit Trail

PHARMA | Compliance Audit, Integrity Inspection & Label Inspection

PHARMA | Speed Detection

BOTTLES | Fill & Seal Inspection

BAGS | IV Solution & Pressure Infusion

SYRINGES | Medical Needles & Syringes

TUBE | Gels & Creams

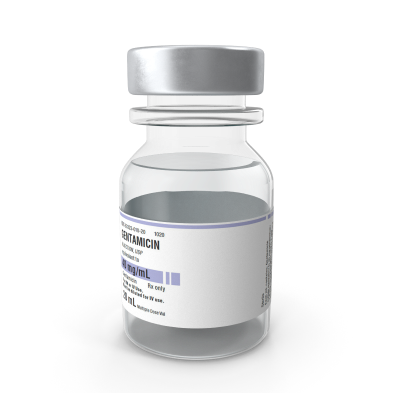

VIALS | Plastic & Glass

PILLS & CAPSULES | Quality Control & Packing

AI BRAIN | Ready to Grow With You

-

PHARMA | Compliance Audit, Integrity Inspection & Label InspectionIn the pharmaceutical industry, compliance, integrity, and precision are paramount. The AI Brain conducts comprehensive compliance audits, meticulously inspecting every aspect of the manufacturing process to ensure adherence to regulatory standards. From vial to tube and beyond, integrity checks to label inspections, it maintains strict quality control, guaranteeing the safety and efficacy of every pharmaceutical product that leaves the facility.

-

PHARMA | Speed DetectionThe AI-Brain's expertise extends to meticulously inspecting the cosmetic aspects of various food items, revolutionizing cut optimization and ensuring the highest standards of visual appeal and quality.

-

BOTTLES | Fill & Seal InspectionThe AI Brain makes sure all baked goods are cooked just right by checking their size, color, and texture with special technology.

-

BAGS | IV Solution & Pressure InfusionFrom salads to snacks, the precise composition of ingredients is essential for both flavor and safety. The AI Brain conducts meticulous ingredient and content analysis, verifying the accuracy of recipes and ensuring proper distribution of ingredients. Whether it's checking for allergens or confirming nutritional information, it guarantees that every product aligns with regulatory requirements and consumer expectations.

-

SYRINGES | Medical Needles & SyringesIn addition to its many other functions, AI vision systems proved one final set of eyes on all products before they are next seen by a client. The AI Brain can quickly and accurately read and interpret information from a large volume of codes, ensuring precision in data processing. Especially important in industries with strict regulations, such as healthcare and food, where accurate tracking and adherence to expiration dates are critical for compliance, this AI automated reading process is much faster than manual QA methods, and improves overall workflow and productivity.

-

TUBE | Gels & CreamsIn addition to overseeing product inspection, CVSS's AI-Brain extends its watchful gaze to all machinery interacting with products within the manufacturing facility. This includes blades cutting meat, conveyor belts, and other critical components. Through rigorous integrity inspections, the AI-Brain meticulously examines machinery to ensure operational integrity and prevent potential hazards.

-

VIALS | Plastic & GlassIn the realm of liquid products like juices, maintaining the integrity of packaging and accuracy of labeling is paramount. The AI-Brain can detect wrinkled or missing parts of labels within (and beyond) the manufacturer's approved parameters, immediately removing them from the line for correction. This proactive approach prevents flawed labels from reaching customers, mitigating the risk of returns, lost sales, and damage to brand reputation.

-

PILLS & CAPSULES | Quality Control & PackingFrom oils to beverages, maintaining purity and integrity is essential in liquid production. The AI Brain specializes in liquid inspection, conducting rigorous contaminant checks and ensuring bottle integrity to safeguard product quality.

Pharma Production Focus:

Automated manufacturing has significantly transformed pharmaceutical production by enhancing efficiency, precision, safety, and speed in various aspects of the manufacturing process. Here are key ways in which automation has impacted production in the food and pharmaceutical industries production.

High-throughput Screening (HTS):

Automated Manufacturing enables automated HTS. This allows for the testing of a massive number of compounds for their biological activity, and in so doing, expedites the screening process of thousands of compounds to more efficiently and accurately identify potential drug molecules/candidates.

Drug Formulation and Manufacturing:

AI Automated Vision Systems are employed in drug formulation and manufacturing processes, ensuring precise mixing, weighing, and dispensing of ingredients. Automated manufacturing systems handle various aspects of drug formulation to achieve consistent and accurate dosages.

Packaging and Labelling:

Automated manufacturing plays a vital role in the efficiency and reliability of pharmaceutical packaging and labelling. From packaging medications into various forms, including blister packs, bottles, or sachets, to ensuring that all products are labelled accurately, automated systems are reducing the risk of errors through preemptive and corrective measures.

Quality Control and Inspection:

Automated monitoring and processing systems are used to ensure quality control and inspection during the manufacturing process. Automated systems are capable of identifying product content (even through dark amber glass), measuring dimensions, and verifying packaging integrity, thereby ensuring that pharmaceutical products meet quality standards.

Pharma Production Focus

CVSS modules have significantly transformed pharmaceutical packaging, bringing benefits in terms of efficiency, accuracy, compliance, and overall productivity to the pharmaceutical companies

CVSS modules Increase efficiency and speed. Automated packaging systems can handle pharmaceutical products at a much higher speed compared to manual operations. This increased speed in packaging helps meet the high demand and production targets more efficiently.

In addition improved accuracy and consistency ensure precise and consistent packaging of pharmaceutical products, reducing the chances of errors in dosages or packaging. The accuracy helps maintain high-quality standards and regulatory compliance in the food and pharmaceutical industries.

Our clients have achieved enhanced quality control for their automated packaging systems. Integrated advanced sensors and cameras are used to inspect the quality of products during the packaging process. They can identify defects, ensure proper labeling, and detect any inconsistencies in packaging, promoting better quality control.

With changing compliance with regulations: our equipment is adaptable, moveable and easily-programmable. CVSS modules help in adhering to strict regulatory requirements in the pharmaceutical industry.

Our automated systems can enforce compliance with labeling, serialization, and traceability standards, ensuring that products meet regulatory guidelines.

Reduced labor dependency has helped packaging processes, leading to cost savings and minimizing the risk of human errors. This allows skilled labor to focus on more complex tasks that require human expertise.

In addition, flexible packaging options can be handled by our CVSS modules; various packaging formats and sizes efficiently. They can easily adapt to different packaging requirements, enabling the pharmaceutical company to package a wide range of products with minimal adjustments.

CVSS modules have helped pharmaceutical companies to offer customized packaging solutions, tailoring product packaging to specific customer needs or market demands without compromising efficiency or accuracy.

Optimized resource utilization automation optimizes the use of packaging materials by accurately measuring and dispensing them, reducing waste, and contributing to cost savings and sustainability efforts.

CVSS automated systems provide real-time monitoring of the packaging process, allowing for immediate intervention if any issues arise. This real-time monitoring also facilitates data collection for performance analysis and process improvement.

Our modules minimize manual handling of heavy materials and reduce exposure to potentially harmful substances, improving workplace safety and ergonomics for workers.

CVSS Modules provide Integration with Enterprise Systems. Automated packaging systems can be integrated with enterprise resource planning (ERP) and manufacturing execution systems (MES), enabling seamless communication and data exchange across the entire production line for improved coordination and efficiency.